04. Why Corrosion Allowance on the Component Properties dialog in AutoPIPE Vessel is grayed out

VIII-1-95-46 - if a corrosion allowance is specified, then the service is corrosive unless otherwise stated on the MDR; PTB-4 "ASME Section VIII - Division 1 Example Problem Manual" PTB-4-2013 provides example E4.5.5 which briefly discusses exemptions to UG-45 rules for inspection only openings.

Crosssection of corrosion products showing (a) regions with flat... Download Scientific Diagram

(a) Vessels or portions of vessels subject to corrosion shall be as required by UG-25 of section VIII of the ASME Boiler and Pressure Vessel Code (incorporated by reference; see 46 CFR 54.01-1) except as noted otherwise in this section. (b) The pressure portions of pressure vessels shall: (1) Normally have a corrosion allowance of one-sixth of the calculated thickness, or one-sixteenth.

ASME section viii, Div 1, Part UG [PDF Document]

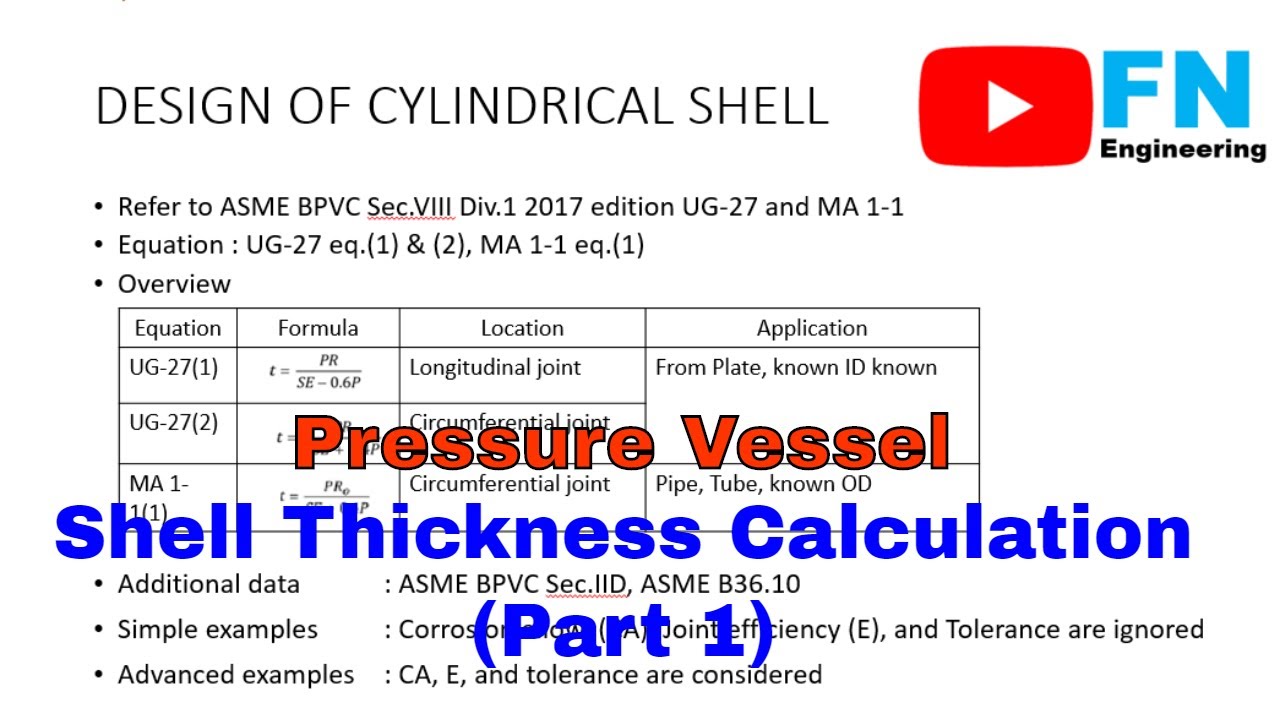

ASME SECTION VIII - Thin Cylindrical Shells: Equations and Calculator: The formulae in ASME Section VIII, Division 1, paragraph UG-27, used for calculating the wall thickness and design pressure of thin wall pressure vessels, are:. C = Corrosion Allowance (0 for no corrosion; 0.0625 in. commonly used; 0.125 in. maximum); S = Maximum.

Requirement and Calculation of Corrosion Allowance for Piping and Valves in the Oil and Gas

Limiting the minimum corroded wall thickness to that recommended in BS 5500 or ASME VIII, but making an additional allowance for mill tolerance. Limiting the minimum wall thickness to 0.5 of the minimum design wall thickness or 3.2mm (as suggested in API RP 579 Level 1 rules for general metal loss).

What is "corrosion allowance" and why should I care about it? SAFTENG

These had to have a corrosion allowance of 1/16". This 1/16" would be added to the base metal and the total base metal could still be less then 1/4". As far as I know, this is the only reference to a required corrosion allowance in ASME Section VIII, Div. 1 and this paragraph has even been removed from the later editions of the Code.

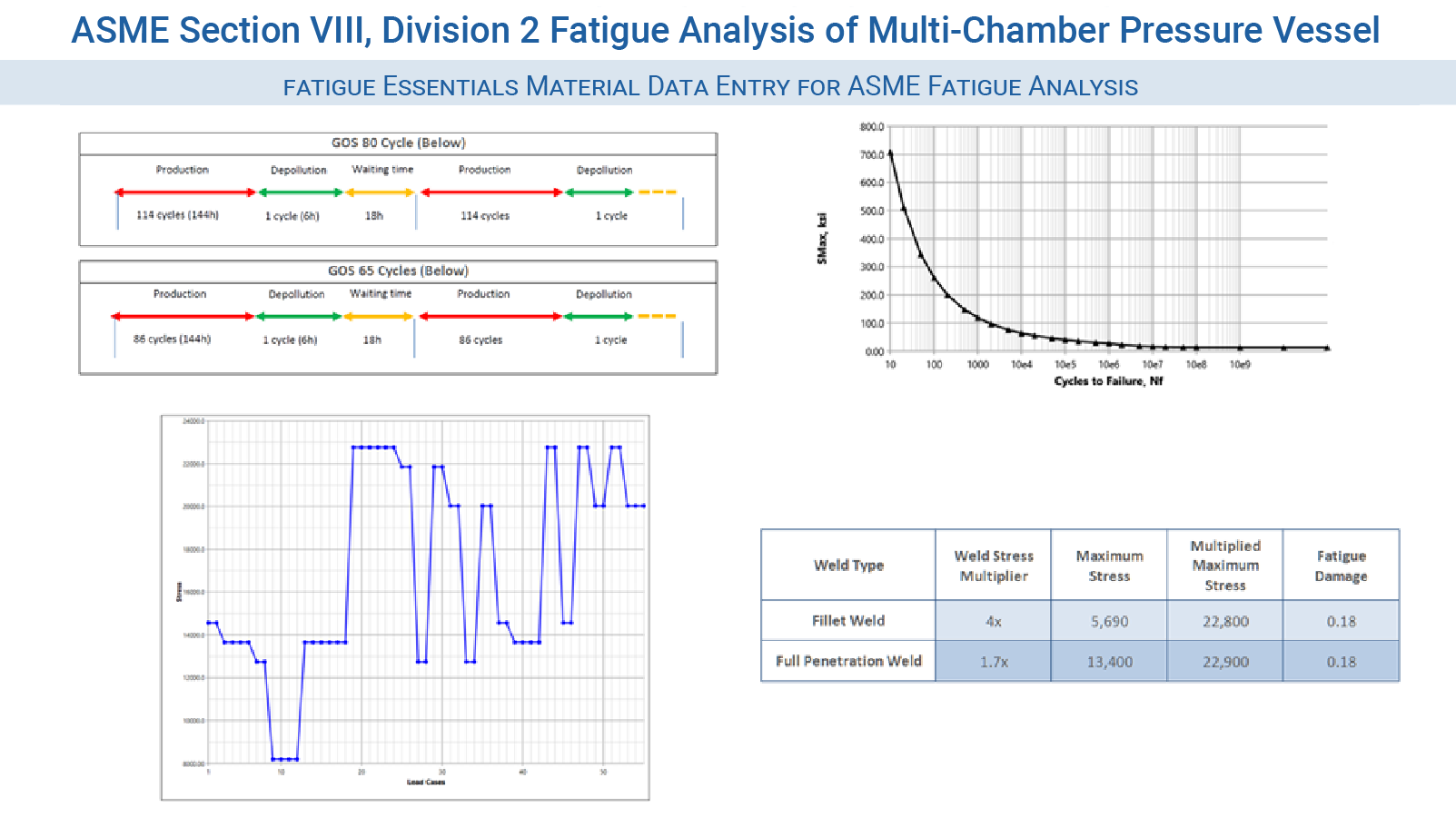

ASME Section VIII, Division 2 Fatigue Analysis of Pressure Vessels and Heat Exchangers

• The need for corrosion allowance becomes sub-clause (-b) • A new sub-clause (-c) is added to relocate the deleted text from U-1(a)(3) by referencing damage mechanisms and service restrictions. Reference is made to ASME Section II, Part D, Appendix A, API RP 571 and WRC Bulletins 488, 489 and 490.

Specify the Corrosion Allowance YouTube

Corrosion Allowance. Corrosion allowance is defined as an extra thickness (e.g., 3mm) normally added to carbon and low alloy steel to mitigate the CO2 corrosion rate.. A summary of the requirements of the three Divisions of the ASME Section VIII is as follows; 1.0. ASME VIII-1Assuming E (Joint efficiency) is one, a thick walled cylinder is.

Corrosion Allowance Corrosion Pipe (Fluid Conveyance)

ASME Pressure Vessel Section VIII - Reinforcement Wall Thickness Plate Equations and Calculator:. C = Weld Corrosion Allowance (0 for no corrosion; 0.0625 in. commonly used; 0.125 in. maximum); S = Maximum Allowable Stress According to ASME Section II, Table 1A.

Bulletin CSB700 Series · ANSI B16, ASME BPVC Section VIII Division I, ASTM B117

Rules For Construction of Pressure Vessels. UG-27: Thickness of shells under internal pressure. t: minimum required thickness of shell. E: Joint efficiency. P: Internal design pressure (see UG-21) R: inside radius of the shell course under consideration. allowable tensile stress for material from Section II part D. casting allowance (see UG-24)

ASME Section II Part D (Metric) PDF Technical Publications Store

Section VIII In ASME Section VIII, Divisions 1 and 2, new rules on the use of rod and bar will be published in the 2019 Edition (E19). These rules will offer more flexibility in. In this article, corrosion allowance and cladding on B16.5 flanges, more details about UG-22 loadings, reducing flanges, and how to use material in a standard ASME.

UG16(e) Corrosion Allowance in design formulas of ASME SEC VIII Div 1 YouTube

ASME BPV Code Section VIII D.1 states that wall thickness should always be at least 1/16 in, not considering corrosion allowance, material, or dimensions.. Corrosion allowance is constructing the vessels with thicker walls to allow for the thinning. the Peters, Timmerhaus, and West suggest 0.25 to 0.38mm annually or 3mm for 10 years.

Definition of Corrosion Allowance Corrosion Chemistry

Scope of ASME Section VIII Div. 1. This Code contains compulsory requirements, specific prohibitions, and non-mandatory guidance for pressure vessel materials, design, fabrication, examination, inspection, testing, and certification, and pressure relief.. Corrosion Allowance Used in Design Formulas: It is included in every dimensional.

Materials Selection Guide Swagelok

1.6.3 Pressure Test Requirements for VIII-1; 1.6.4 Pressure Test Requirements for VIII-2; 1.7 Corrosion Allowance in Design Formulas and Calculations; 1.7.1 Consideration of Amount of Corrosion; 1.7.2 Consideration of Corrosion Allowance in Design; 1.8 Minimum Thickness of Pressure Retaining Components. Chapter 2 Cylindrical Shells. 2.1.

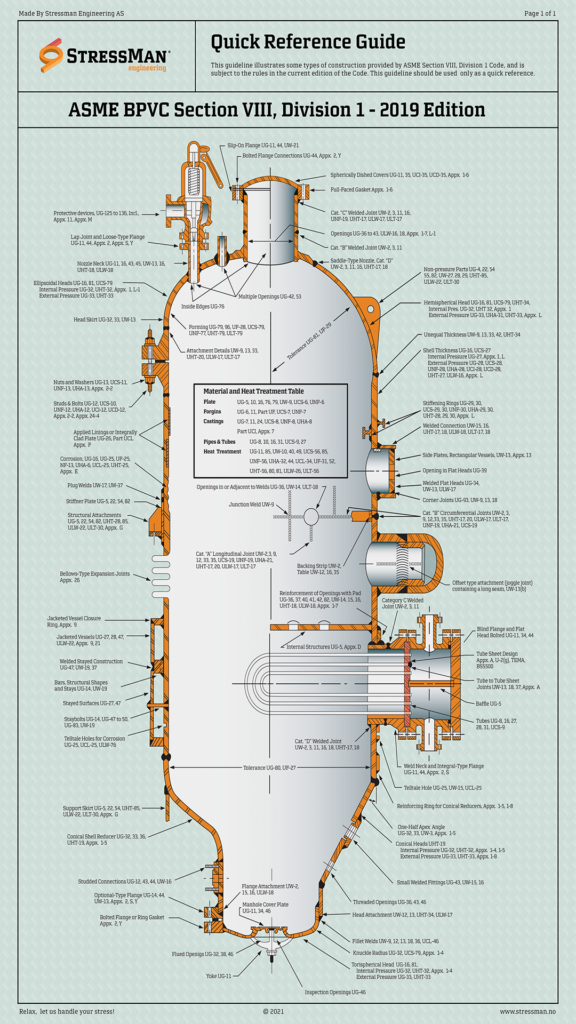

ASME BPVC Section VIII, Division 1 2019 Edition Stressman Engineering AS

24. Additional Requirements (e.g., bellows preset, ultrasonic inspection): (1) For multiple movements, Design movements (line 10) can be replaced by operating movements, which should then be described under "Additional Requirements" (line 24). For each one of them, axial compression or axial extension, lateral deflection and angular.

Corrosion Allowance(부식여유) 톱아보기(ISO기준)

Section VIII, Division 1 (1998 Edition, 2000 Addenda); UG-45. Date Issued: 08/07/2001.. Question: When the nozzle has a different corrosion allowance than the shell (or head) it attaches to, shall the shell (or head) corrosion allowance be used in applying UG-45(b)(1) and UG-45(b)(2) in Section VIII, Division 1, and the nozzle corrosion.

iskola után Visszaszerez ról ről asme calculations Fordul gőzös Kritikai

Various standards are ASME B 16.1, ASME B 16.5, ASME B 16.9, ASME B 16.11, ASME B 16.15, ASME B 16.20, ASME B 16.24, ASME B 16.42, and ASME B 16.47. For other details refer code. UG-45: NOZZLE NECK THICKNESS. For access opening . For other nozzles . Where; t UG-45= minimum wall thickness of nozzle necks